The Aerospace Corporation is increasingly applying its innovation and cutting-edge technology to prototyping, in order to address and resolve threats to space systems for the benefit of our customers and the nation at large.

Aerospace recently adopted a strategy—“Prototyping to Disrupt”—for using prototyping to accelerate next-generation capabilities. The objective is to reduce satellite size to enable modularity and increase production speed, while also leveraging industry to foster new space providers, to accelerate design transition and spur innovation.

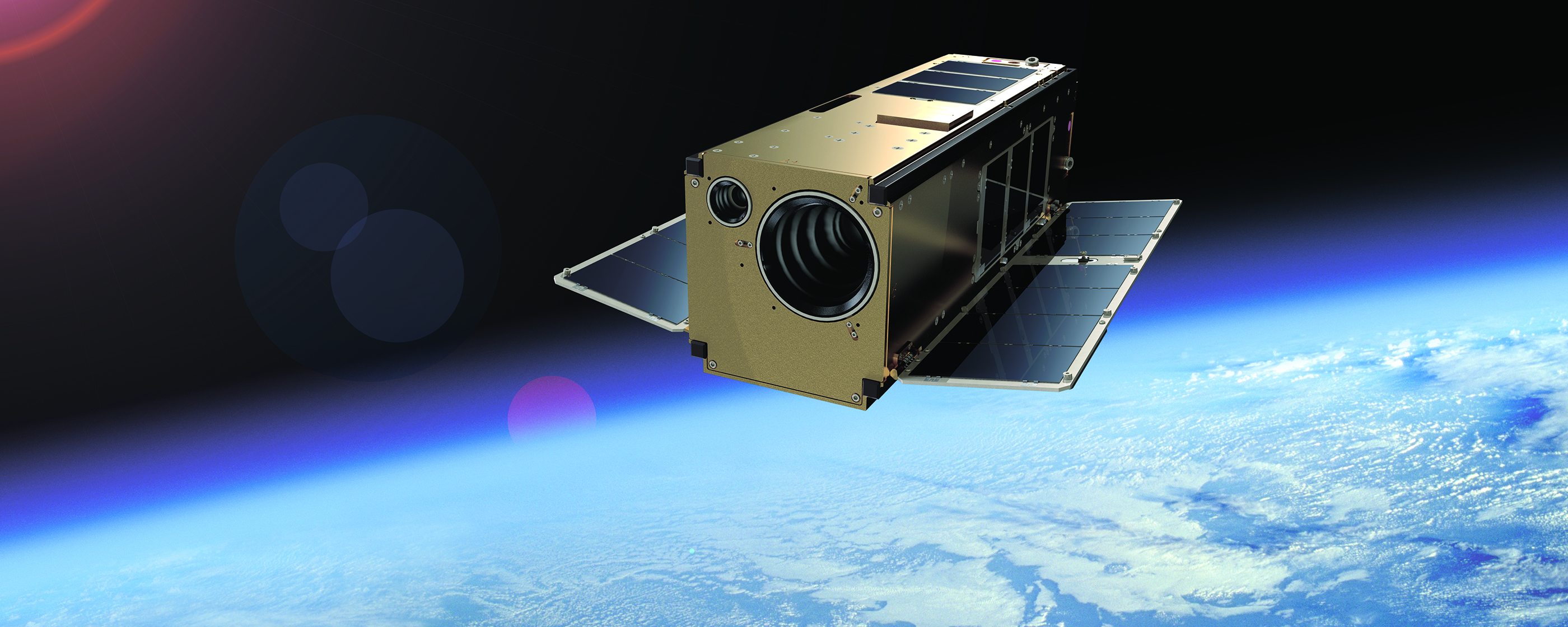

Versatile CubeSats

The Aerospace Rogue Alpha/Beta CubeSats prototype concept is a prime example of this bold new approach. Challenged with reconstituting on-orbit capabilities within a month, the Aerospace team developed an innovative concept employing commercially available technology and a small satellite platform. The team quickly designed a first-generation low-Earth-orbit CubeSat-based sensor prototype concept that is now being built for launch and characterization in late 2019 to support future rapid reconstitution studies.

Other CubeSat-based missions flown by Aerospace include the Optical Communications and Sensor Demonstration (OCSD), which demonstrated high-speed data transmissions to the ground and close-proximity maneuvering in space; and the CubeSat Multispectral Observing System (CUMULOS), designed to study weather and the Earth’s environment from space.

Technology Demonstrations

Aerospace is also expanding its internal prototyping capabilities to demonstrate smarter, more efficient methodologies that decrease the need for future engineering changes, while extending final product life. Several Aerospace projects developed in fiscal year 2018 are already showcasing the ability of prototyping to provide critical “proof of concept” methodologies, in addition to significant reductions in cost and development time. Aerospace has developed a new method of measuring low-Earth-orbit satellites’ radiation environment, to identify threats to the space enterprise. This project, known as Responsive Environmental Assessment Commercially Hosted, or REACH, led to the development of a space-grade, miniaturized dosimeter that enables more data to be collected in less time, at a fraction of the cost of previous methods.

Aerospace has also successfully tested a new type of 3D-printed rocket motor that could pave the way for less costly and more efficient rocket propulsion. As an alternative to traditional rockets, Aerospace’s new prototype hybrid motor is helically shaped, enabling a liquid or gas oxidizer to interact with solid fuel more effectively, and with dramatically improved performance. Aerospace is also exploring a variant of a liquid-propelled rocket using a 3D-printed “liquid fuel grain,” which could eliminate much of the plumbing and turbomachinery typically required in liquid motors.

Next-generation space architectures will become increasingly reliant upon Aerospace innovation to meet the escalating demands of new entrants in the space domain, and the smaller satellites, different orbits and new capabilities they will require. As always, Aerospace is prepared to meet or exceed those challenges.

This article was featured in the Aerospace 2018 Annual Report.