Throughout the country, state governments are developing plans for businesses to resume normal or phased on-site operations while still limiting the spread of the COVID-19 virus. These plans include the rapid identification of people who may be infectious. Temperature measurement is currently being used as a precautionary screening method to detect the elevated body temperatures that can signal potential COVID-19 infection.

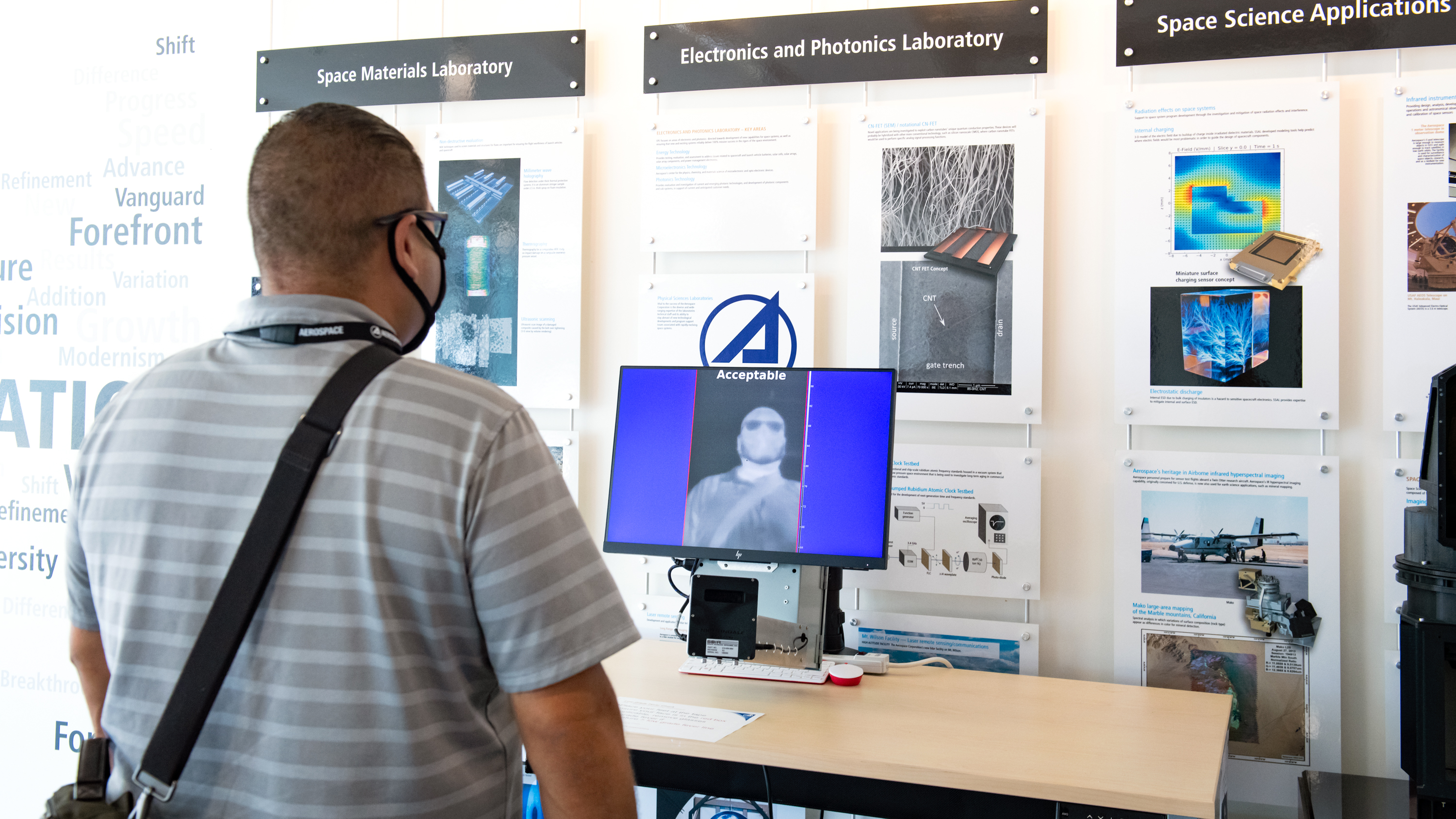

As The Aerospace Corporation continues its phased return of employees to campuses, every precaution is being taken to ensure that the process is thoughtfully and carefully implemented, and that every safety concern is addressed to curtail the spread of the virus. Aerospace employees returning to office may notice new non-contact temperature assessment devices developed by their own colleagues in xLab and the Physical Science Laboratories (PSL). The Aerospace prototype (dubbed “The T-Case”) consists of carefully selected and coordinated off-the-shelf parts, with simplified software written in robust custom code that has achieved high system stability.

Though commercially available infrared thermometers are now in wider use, their accuracy issues have prompted a need for a device that can perform the same functions while providing more contextually accurate and informed temperature readings. The T-Case is named after Dr. Toby Case, Resident Scientist at Aerospace, who says that the key is to couple infrared imaging with temperature reference.

“We in PSL were determined to find a way to make a reliable, NIST (National Institute of Standards and Technology) traceable, non-contact temperature measurement device as we return to work in the ‘new normal’,” Case said. “My role was to devise and implement a basic prototype that includes IR imaging and a temperature reference, and to make the prototype fast.”

Commercially available thermal imaging cameras and infrared telethermographic systems (commonly known as infrared thermometers) have become essential tools in the virus-fighting arsenal. Among the advantages of these non-contact devices is that they can quickly measure and display a temperature reading so that a large number of people can be evaluated individually. Furthermore, these devices offer the advantage of speed, as the lack of contact obviates the need for cleaning the device after each use.

Unfortunately, these devices can also misread normal temperatures as elevated, and often lack the imaging refinement needed to distinguish a high body surface temperature caused by one’s environment (such as a warm room or hot summer day) from one caused by an infection. Hence, these devices are in the unfortunate position of being both precise and inaccurate at the same time.

The T-Case improves substantially upon available technology by not relying on available lighting conditions to process faces using the visible spectrum (which often renders erratic body temperature readings). While many other systems read forehead temperature, this approach is prone to variation due to the presence or absence of sweat. In contrast, the T-Case relies upon low noise measurement to achieve simple image processing when reading human tear duct temperature, a far more reliable way to estimate internal human body temperature. Most importantly, the T-Case prototype represents a triumph of the resourcefulness and innovation that are Aerospace’s stock in trade. The devices were assembled in xLab, which has just undergone a complete renovation to allow Aerospace to more effectively build instruments and prototypes.

“The T-Case was an opportunity for xLab to demonstrate its agility and flexibility during challenging times,” said Lynn Friesen, Principal Director of xLab. “xLab’s expertise as ‘developers of prototypes’ was brought to the fore as xLab staff quickly engineered and fabricated the thermal imagers Aerospace will use to ensure employee health and safety. This is remarkable in a time when on site staff are at a minimum because of Covid-19 and the newly designed fabrication and assembly labs are still getting organized. The T-Case was one of the first new prototypes out of the new facility, and the side-by-side – metaphorically speaking – rush-to-the-finish with our PSL colleagues was a morale and team-building experience.”

To safeguard protected health information, the T-Case ensures a high level of privacy as it cannot store or transmit data. In addition, its interface is readily customizable, minimizing user error by allowing the user to select high contrast color change when a fever is detected.

“The T-Case is a NIST-traceable human temperature measurement system that presents a vast improvement over what’s available commercially at present,” Case said. “Thanks to the success of the prototype, we've finalized a design for scaling up and are making 10 more systems with basically the same functionality as the prototype that will be distributed between three campuses. This system will serve as one of many necessary steps to provide for employee safety as we transition through our return-to-office phases. The system provides for highly accurate screening, which is essential for coworkers to be and feel safe.”