For many years, the space industry has been seeking reliable methods to predict and mitigate the risk of conductive whiskers forming in electronic components. These whiskers, which can grow on the tin leads and terminals used to attach chips and components to circuit boards, have been implicated in past failures on orbit. One common approach to mitigating risk is to solder the pure tin leads using leaded solder. In many cases, this solder attachment does not require significant process changes. The solder used to attach the components to printed circuit boards mixes into the existing pure tin lead finish, and such components are said to be "self-mitigating."

Tin Whisker Self-Mitigation

A 2010 study by Raytheon indicated that the geometry of component leads could be used to predict self-mitigation—at least for one common fabrication technique. More recently, researchers sought to determine whether the same was true for a wider range of chips and fabrication techniques. If so, then manufacturers could use tin-terminated components in certain cases without further mitigation.

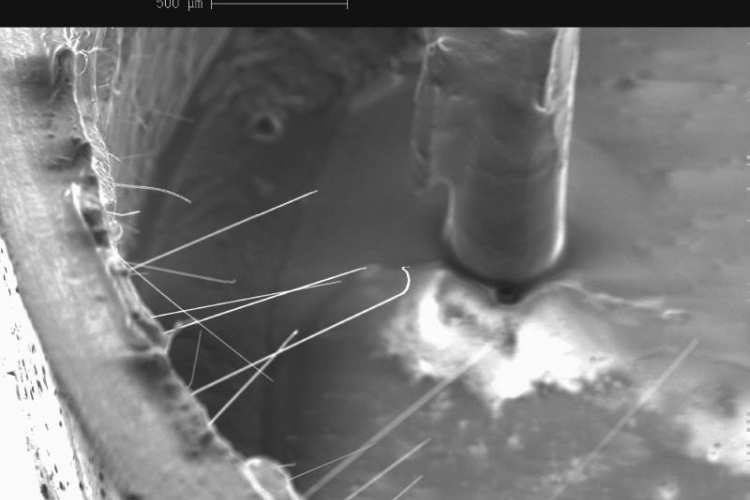

The study examined several different component packages, circuit-board finishes, pad sizes, and manufacturing processes. Seven assemblers were provided with eight boards, each of which would contain more than 50 components. The finished boards were then inspected via x-ray fluorescence and scanning electron microscope; some were further examined using an M4 Tornado spectrometer.

Tin Whisker Study Results

The results indicate that package geometry is the most significant factor for achieving self-mitigation. Most components exhibited a moderate probability of self-mitigation. Some—in particular, the 0603 and SO14G chips—were nearly certain to self-mitigate under all process conditions, while others would do so only for a particular process. One chip—the 0612—was highly unlikely to self-mitigate. Process also plays an important role; vapor-phase and oven reflow can produce different results for the same parts, as can the peak oven temperature. On the other hand, board finish does not seem to affect self-mitigation.

The study yielded additional insights. For example, it showed that x-ray fluorescence is effective for evaluating self-mitigation, as confirmed by subsequent cross-sectioning and microscopy. Short-term aging of components (about a year) did not seem to affect self-mitigation, but longer aging periods (about five years) did in some instances. Lead geometry affects self-mitigation for quad flat packages, with shorter leads exhibiting a higher probability than longer and taller leads.

Self-mitigation is attractive for manufacturers, as it does not add any process steps or material requirements. This study should help increase confidence in self-mitigation as an effective approach to controlling tin-whisker growth.

This story appeared in the December 2018 issue of Getting It Right, Collaborating for Mission Success.

Subscribe to Getting It Right