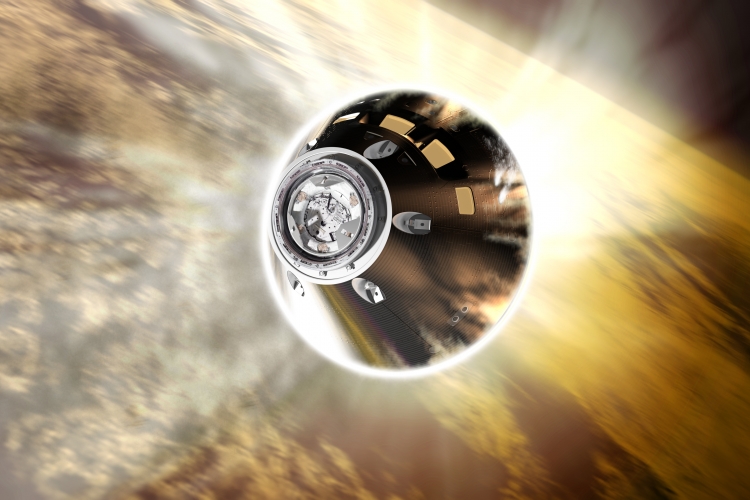

If all goes according to plan, NASA’s Orion space capsule will transport its first crew of astronauts to the moon by 2024. When it comes screeching back through Earth’s atmosphere, it will generate temperatures hot enough to melt rock. To protect the capsule and its inhabitants, Orion is equipped with an advanced heat shield designed to endure the extreme conditions of the rapid descent. In fact, it’s so effective, even sound has a hard time penetrating it.

That’s a problem, at least here on Earth. The heat shield is a critical component, and needs to be thoroughly tested before flight, as the slightest flaw can be catastrophic. NASA tried many methods to probe the heat shield material, with limited success. Traditional nondestructive methods, such as x-ray and ultrasonic inspection, were simply not up to the task.

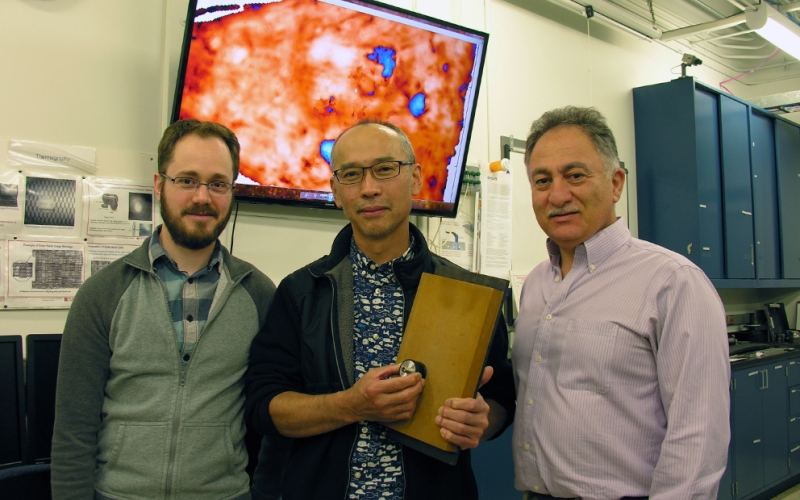

NASA then asked The Aerospace Corporation to apply its considerable expertise in nondestructive evaluation (NDE) to testing the Orion's shielding. According to Dr. Shant Kenderian, director of the Materials Processing Department in the Space Materials Laboratory, Aerospace has a reputation for tackling the most frustrating testing problems. "The NDE staff routinely takes on inspection challenges that other experts have deemed undoable," he said. "The easy ones don’t come to us."

NASA supplied samples of the heat shield material, with known defects in them.Working with these samples, Kenderian’s team arrived at a unique technical solution: they combined a special low-frequency wave generator with signal processing techniques that allowed them to tailor the frequency, duration, size, and shape of ultrasonic bursts. By processing multiple echoes from a single scan, they were able to detect relative changes in the bonding region, regardless of the material uniformity. Using additional information from the phase of the reflected waves, they were able to outline each flaw with high precision.

Incorporating all these techniques into a single prototype system enabled the team to create highly accurate maps showing the location, size, and shape of poorly bonded regions, simply by performing a two-dimensional ultrasound scan of the heat shield’s exterior.

Developing the technique even further, Aerospace built and demonstrated a portable unit for use in the field. The heat shield material cannot be easily removed from the vehicle without causing damage, but NASA engineers can use the hand-held probe to scan the structure and get images back in real time.

"Aerospace has one of the most advanced NDE laboratories in the country," Kenderian said. "Not only is it equipped with a wide range of capabilities, but it is run by an innovative staff with advanced degrees in materials science, physics, electrical engineering, and mechanical engineering."

The Aerospace technique was successfully demonstrated on a manufacturing design unit. The effort will enable NASA to verify and repair, as necessary, the heat-shield construction and make well-informed risk assessments for the future. It may also serve to save astronaut lives.

"This project is a prime example of the role Aerospace can play in solving critical problems on a national level," Kenderian said.

In recognition of this innovative work, NASA presented Kenderian the Engineering Excellence Award while the whole Aerospace team along with NASA staff received a Team Award.