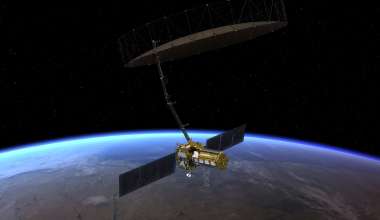

The commercial space economy continues to expand at an unprecedented rate. Private companies are now leading space system and infrastructure development. Despite this rapid growth, long-standing barriers such as the reliance upon established technologies continue to impede the rapid deployment of new and innovative space capabilities.

The Aerospace Corporation is enabling commercial space growth and government partnerships by providing controlled environments that effectively replicate space to verify and validate new capabilities. The use of state-of-the-art testbeds and proving grounds accelerates the path to flight validation and deployment for innovative commercial space capabilities. If leveraged by the space enterprise to scale, this approach could ultimately lead to expedited pathways to deployment and a new, transformative era of space marked by continually evolving space ecosystems.

Bypassing Barriers, Fast-tracking the Future

One of the most intractable challenges to realizing space innovation is the “flight-proven” paradox, a dilemma in which new technologies that have cleared the infamous development “valley of death” still lack flight heritage and struggle to gain the confidence of the investors, insurers, buyers and regulators who are critical gatekeepers to deployment in space. Yet these innovative solutions cannot gain that heritage—and that confidence—without first being flown.

“The reliance on flight-proven tech is a byproduct of how the space community traditionally built everything for specific ‘one and done’ mission needs, and development timelines took as long as needed to build the necessary trust to launch and deploy in space,” said Ron Birk, principal director of the Space Enterprise Evolution Directorate (SEED) at Aerospace. “That model doesn’t work in the current era, when speed is the need and harnessing the pace of commercial innovation is so desirable.”

This creates a situation where only proven technologies are selected for deployment, preventing innovative new systems from entering operational use at the pace they are being developed. As a result, companies attempting to introduce new propulsion systems, spacecraft designs, or advanced satellite technologies often face steep hurdles in proving their viability for space missions.

Advancing Innovation Through Testbeds

A significant development in breaking the flight-proven paradox is the Accelerating Space Capabilities 100 (ASC-100) initiative. Recently announced by Aerospace and the Space Information Sharing and Analysis Center (Space ISAC), ASC-100 is an international federated network of credentialed testbeds and proving grounds commercial companies can use to simulate real-world space operating conditions. Aerospace provides physics and engineering expertise for testing conducted through the ASC-100 initiative, drawing on significant experience supporting commercial space companies within Aerospace’s own laboratory and testbed capabilities.

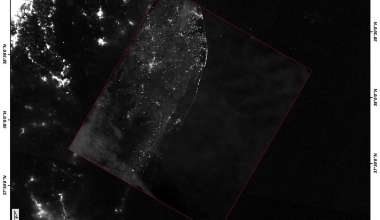

Space systems manufacturer Swissto12 recently tested three electric thrusters inside Aerospace’s EP3 chamber, a unique 14-ft diameter by-30-ft cryopump facility with enormous pumping speed (1 million L/sec) that conducts thruster tests and measures radiated emissions within a flight-like vacuum environment. The Swissto12 tests involved an extensive 11-phase test plan with readiness reviews, test boards and a final report, all conducted with careful coordination between Swissto12 and Aerospace engineers.

Another commercial customer, K2 Space, worked with Aerospace to test its 20-kW Hall thruster, the largest of its kind under commercial development. This propulsion system is critical for the next generation of large, high-powered spacecraft, benefiting from the robust third-party performance validation provided by Aerospace.

"By providing versatile and highly adaptable testing environments, Aerospace’s Propulsion Labs play a critical role in bridging the gap between groundbreaking innovation and flight heritage. These facilities allow for rapid iteration and validation of propulsion technologies, ensuring novel concepts can be thoroughly vetted and refined under realistic conditions before they ever leave Earth," said Dr. Andrea Hsu, a senior engineer at Aerospace’s Propulsion Systems Laboratory (PSL). "This approach not only accelerates the deployment timeline; it also instills confidence in both commercial and government stakeholders by demonstrating that new systems are ready for the rigors of space."

Some of the companies Aerospace supports require custom test configurations for their unique systems. When Astranis engaged Aerospace to conduct quick turnaround testing of its electric propulsion string, Aerospace commissioned the MudPie test facility, a specialized high-speed vacuum chamber, to test various low-power Hall thrusters using alternate chemical propellants. The facility allowed Astranis to debug power electronics efficiently without the logistical constraints of a larger test site. Astranis has since established its own test facilities at its Pier 70 headquarters in San Francisco for future spacecraft development.

Expediting Flight-proven Equivalency

By providing commercial companies with access to propulsion chambers and other testbeds, Aerospace is accelerating the deployment of new space capabilities by enabling companies to prove their systems without waiting for limited flight opportunities. Through initiatives like ASC-100, Aerospace and Space ISAC are working to resolve long-standing impediments to space innovation and build trust in mature, test-proven technologies at enterprise scale.

"There’s greater emphasis for government acquirers and integrators to deliver innovative solutions more quickly, and they have a growing commercial supplier marketplace to source from,” said Birk. “Many capabilities are being developed faster than we can fly them. Streamlined access to testbeds and proving grounds will help build confidence and will accelerate the deployment of many innovative space capabilities to space within a shared timeframe, where they will interact in evolving space ecosystems.”

These efforts go beyond individual projects. They represent a shift toward a more agile, innovation-driven space ecosystem in which commercial developers and operators, government buyers and regulators and the investment community all work in lockstep to achieve the mutual objective of more rapid acquisition and deployment of innovative space capabilities. By lowering barriers to entry for new technologies, Aerospace is fostering a more dynamic industry that can rapidly integrate advancements into space missions. This will ultimately enhance the resilience and capabilities of space operations, benefitting both government and commercial stakeholders.

“Operating in space is hard, and trust is crucial,” said Birk. “We need to streamline the path to the trust that flight-proven status provides, building confidence in innovative space capabilities as they reach operational readiness.”

To learn more about Aerospace's facility for next-generation EP testing, please consult the Aerospace EP3 factsheet.