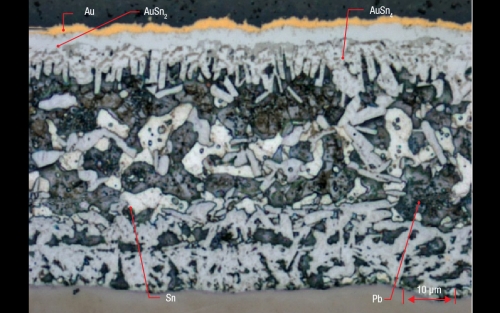

Gold plating on joints to be soldered should be removed to less than 3 percent gold by weight. Formation of gold/tin intermetallic compounds during soldering may result in an embrittlement of the tin/lead joint when less than 95 percent of the gold is removed from gold-plated components prior to soldering.

Gold embrittlement can result in solder joint loss of connectivity that may initially pass electrical testing but later fail during environmental testing or mission operations. It can also result in costly unit rework, reduced mission life, reduced mission data, increased operational complexity, loss of redundancy, and mission failure.

As preventative actions, contractors should implement gold mitigation requirements in their parts, materials and processes (PMP) plan and IPC-J-STD-001, and flow the requirements to their suppliers that perform soldering of gold-plated parts. Suppliers should have sufficient capability to meet the tinning/gold mitigation requirements, and the receiving inspection process should verify incoming part compliance to these requirements.

For more information, contact Thanh T. Tran, 310.336.1159, thanh.t.tran@aero.org

This story appeared in the September 2018 issue of Getting It Right, Collaborating for Mission Success.

Subscribe to Getting It Right