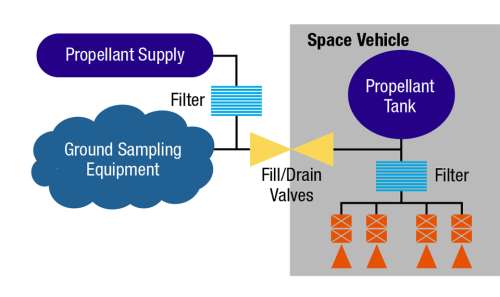

Propellants loaded into a space vehicle must meet contamination and debris tolerance requirements to avoid potential mission impacts. Samples of the propellant prior to satellite loading are tested to ensure the quality and cleanliness. A recent program failed the particulate check, but it was later determined that the ground equipment—not the propellant—may be the source of contamination. Sampling procedures

Failure of the process to properly sample underlines the need to carefully control testing and implement cleanliness controls. Potential impacts from introduced contamination may lead to launch delay, increased satellite internal contamination, and/or leakage of fill valves.

This story appears in the March 2019 issue of Getting It Right, Collaborating for Mission Success.

Subscribe to Getting It Right