Since the days of Explorer 1, marrying a satellite’s payloads to the bus that provides power, telemetry and communications has been a complex, time-intensive process unique to each particular mission.

But in a space environment where agility is increasingly prioritized and resiliency is an overarching imperative, a team of Aerospace employees is working on a vision of the future where integrating the payload and bus of a satellite is almost as easy as plugging a USB drive into a computer.

“For most satellites, the payload and bus are designed and built together, each one’s timeline and resources dependent on the other,” said Brandie Rhodes, an engineering specialist with iLab. “Right now, what we’ve been really focusing on is, ‘Can we decouple those processes in a way that is beneficial to everyone?”

Aerospace scientists and engineers are pursuing a number of initiatives through iLab’s Ventures program with the shared goal of advancing the use of modularity in satellite design, a key enabler for future space missions.

In a modular world, payloads could be designed independently from buses according to a shared set of standards. That modular framework would allow for the two components to be integrated quickly ahead of launch while providing assurance that they’ll function as intended on orbit.

Progress in this area promises to unlock a range of new capabilities, from greater production efficiency for manufacturers to greater flexibility in designing satellite constellations. It could even enable critical payloads to be flown on different satellite buses and/or launch vehicles depending on availability and timeline, allowing for a much more rapid response to potential needs.

Plenty of challenges lie ahead of this modular future, most notably developing a set of technologies and standards that provide the cost savings and reliability to win over an industry that for decades has relied on proprietary, highly-customized satellites.

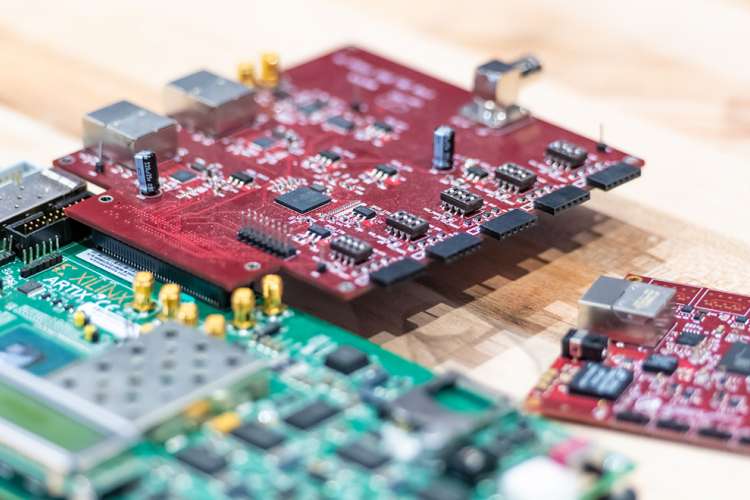

Aerospace is working to enable this shift by tackling the hard problems standing in the way, exploring the hardware and software that would form the foundation of a system that could be adopted by the wider industry.

The Aerospace team’s initial efforts are organized around addressing what it would take to integrate and launch the payloads and bus of a satellite within 24 hours, a scenario with real-world potential for use in rapid reconstitution of satellite fleets during dynamic operations.

Their work includes looking at adapter designs and supporting systems that would allow unique payloads to interface with commercially-available CubeSat buses.

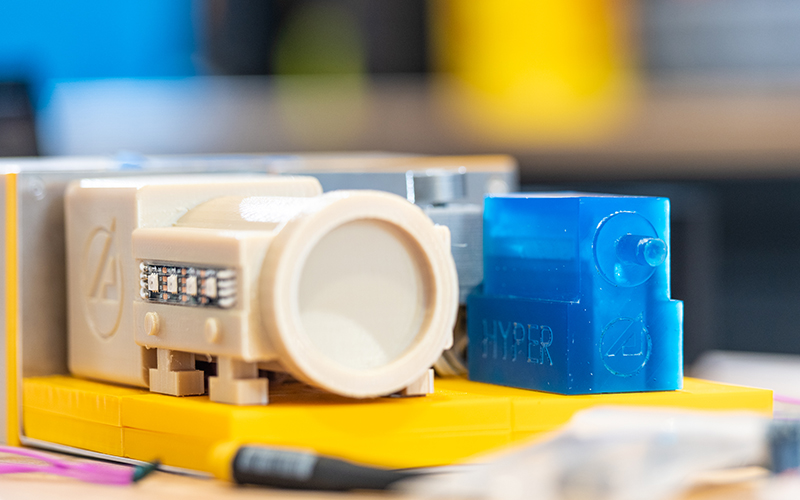

The initial output includes Handle, a physical adapter that would bridge payloads and bus to provide the needed power, command, data and timing capabilities.

A related effort, Bender, is a low-power Ethernet network that would allow various CubeSat subsystems to connect to a single, reliable network for transferring data, rather than the ad-hoc interfaces used today. Source code for Bender was recently made publicly available.

“You end up reinventing basically the same wheel over and over again. That’s what we’re trying to avoid with modularity by avoiding duplicated effort,” said Alexander Utter, the senior engineering specialist leading Bender. “It’s a way of encapsulating complexity and making sure everybody only needs one interface.”

The modular revolution won’t happen overnight, but the immense potential the concept offers means it will continue to be closely studied. Aerospace’s unmatched technical expertise and role as a trusted partner across the industry make it uniquely suited to deliver results.

“They’re big ambitions. There is a strong desire in both government and industry circles to move away from one-off designs” Rhodes said. “With iLab Ventures we’re discovering the technologies and ideas to make that happen.”